DX Series

DX 200-3

For the revolutionary and competitive market DX 200 series serves a platform to perform greater on high productivity and superior surface finish as it has derived from continuous development and innovation since Jyoti has begun to CNC machine tool manufacturing. The series is most demanding due to its rigid step-up structure and construction with versatile application which covers optimum dimension ranges of workpiece.

Key Features

| DX 200-3 | ||

| Swing Over Bed | mm | 500 |

| Std. Turning Dia. | mm | 250 |

| Max. Turning Dia.* | mm | 320 |

| Max. Turning Length* | mm | 320 |

| Slides | ||

| X-Axis Travel (Cross) | mm | 175 |

| Z-Axis Travel (Longitudinal) | mm | 320 |

| Rapid Feed (X & Z Axis) | m/min | 24/24 |

| Main Spindle | ||

| Spindle Motor Power – Siemens | kW | 9.8/7.5 |

| Spindle Motor Power – Fanuc | kW | 7.5 / 5.5 |

| Spindle Speed Range | rpm | 50-4000 |

| Spindle Bore | mm | 55 |

| Spindle Nose | A25 | |

| Max. Bar Capacity | mm | 44 |

| Turret | ||

| No. of Station | 8 | |

| Max. Boring Bar Dia. | mm | 40 |

| Tool Size (Cross Sectional) | mm | 25 x 25 |

| Tail Stock | ||

| Quill Dia. | mm | 85 |

| Quill Stroke | mm | 120 |

| Thrust | Kgf | 300 |

| Accuracy (as Per VDI/DGQ 3441) | ||

| Positioning Uncertainty (P) | mm | 0.007 |

| Repeatability (Ps Medium) | mm | 0.005 |

| Other Data | ||

| Machine Weight (Approx.)# | Kg | 2500 |

| Machine Dimension (Approx.)#: | ||

| Length | mm | 2163 |

| Width | mm | 1465 |

| Height | mm | 1685 |

- 3-point Leveling System

- High Speed Servo Turret

- High Reliable Spindle

- Tailstock

- Ergonomic Design

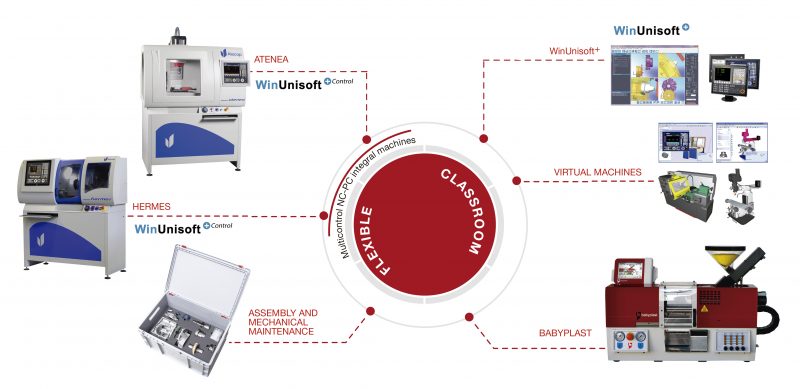

MECHANICAL MANUFACTURING

- CNC Programming.

- Operator skills.

- Implementation and maintenance of CNC machines.

- Machines of different sizes and features.

- Control of machines via PC, using multi-panel software (Fanuc, Fagor, Siemens).

- Software for CNC programming and simulation in different programming languages.

- Control of machines via industrial CNC.

- Virtual machines.

- Adjustment

- Bench grinders

- Sharpeners

- Welding drills

- Saws

- Tracing table

- Pneumatics

- Cad

- Safety equipment utensils and tools

VMC Performance Series

VMC nvu Series

To match greater accuracy and higher reliability ay higher speed the series is developed with high dynamic structure support and rapid axis acceleration. Broad base and twin layer heavy column improves vibration damping and balance the machine during machining with heavy cutting parameter. Broad table supported by precision LM guideways to offer high load carrying capacity. The series is best suited for high material removal from casting and forging preferred in die mould application.

Key Features

| VMC 430nvu | VMC 850nvu | VMC 1260nvu | VMC 1370nvu | ||

| Table | |||||

| Table Size | mm | 600 x 300 | 1000 X 530 | 1400 X 630 | 1500 X 700 |

| T-Slot Dimension | mm | 3 X 14 X 100 | 4 X 18 X 100 | 5 X 18 X 125 | 5 X 18 X 125 |

| Distance from Floor to Table | mm | 880 | 965 | 1090 | 1090 |

| Max. Load on Table | kgf | 200 | 500 | 1200 | 1200 |

| Capacity | |||||

| X-Axis Travel | mm | 400 | 820 | 1220 | 1300 |

| Y-Axis Travel | mm | 300 | 510 | 600 | 700 |

| Z-Axis Travel | mm | 400 | 510 | 610 | 700 |

| Dis. From Spindle Face to Table Top (Min.-Max.) | mm | 200-600 | 150-660 | 150-760 | 150-850 |

| Feed | |||||

| Rapid Traverse (X, Y & Z Axis) | m/min | 40/40/32 | 24 | 24 | 20 |

| Cutting Feed | m/min | 10 | 10 | 10 | 10 |

| Main Spindle | |||||

| Spindle Speed Range | rpm | 10000 | 10000 (6000) | 10000 (6000) | 10000 (6000) |

| Spindle Motor Power -Fanuc | kW | 7.5/5.5 | 11/7.5 (15/11) | 11/7.5 (15/11) | 11/7.5 (15/11) |

| Spindle Motor Power -Siemens | kW | 7.2/5.5 | 14.3/11 (15.6/12) | 14.3/11 (15.6/12) | 14.3/11 (15.6/12) |

| Front Bearing Bore | mm | 60 | 70 | 70 | 70 |

| Spindle Nose | BT 40 | BT – 40 | BT – 40 | BT – 40 | |

| Automatic Tool Changer | |||||

| Number of Tool | 20 | 20 | 20 | 20 | |

| Max. Tool Dia. Pockets (All/Adj. empty) | mm | 80/150 | 80/125 | 80/125 | 80/125 |

| Max.Tool Weight | kg | 7 | 7 | 7 | 7 |

| Max.Tool Length | mm | 200 | 250 | 250 | 250 |

| Accuracy (As per VDI/DGQ 3441) | |||||

| Positioning Uncertainty (P) | mm | 0.010 | 0.010 | 0.010 | 0.015 |

| Repeatability (Ps medium) | mm | 0.005 | 0.005 | 0.005 | 0.007 |

| Other Data | |||||

| Weight # (Approx.) | Kg | 3500 | 5700 | 8560 | 9000 |

| Dimension # (Approx.) | |||||

| Length | mm | 2420 | 3700 | 2830 | 2900 |

| Width | mm | 1700 | 2030 | 3140 | 3200 |

| Height | mm | 2650 | 2830 | 3150 | 3250 |

- 3 Point leveling

- 90° tilting operating panel

- TPM friendliness